Carbon Fiber Reinforced Polymer (CFRP) Optics Quality Assessment for Lightweight Deployable Optics

Jonathan R. Andrews1, Ty Martinez1, Sergio R. Restaino1, Freddie Santiago1, Christopher C. Wilcox1, Scott W. Teare2, Robert C. Romeo3, Robert N. Martin3 jonathan.andrews@kirtland.af.mil

Abstract: The Naval Research Laboratory and Composite Mirror Applications (CMA) have been working together for several years on the development of Carbon Fiber Reinforced Polymer (CFRP) optics and telescopes. We have documented the potential advantages of this technology in several other publications, including structural, thermal and weight advantages over traditional steel and glass optical systems. In this paper we present results of a battery of optical tests done on various CFRP replicated mirrors. Our goal is to demonstrate not only the optical quality of such mirrors but also their reproducibility and stability. We show test results on a sample of four mirrors. We performed extensive optical tests and also stability and repeatability tests. These tests are geared towards proving the use of this technology for a variety of optical applications including use in our CFRP telescopes.

Naval Research Laboratory

Remote Sensing Division, Code 7216 3550 Aberdeen Ave SE

Kirtland AFB, NM 87117

Ph: 505-846-6037

Fx: 505-853-2498 jonathan.andrews@kirtland.af.mil ty.martinez@kirtland.af.mil sergio.restaino@kirtland.af.mil freddie.santiago@kirtland.ad.mil christopher.wilcox@kirtland.af.milNew Mexico Institute of Mining and Technology Electrical Engineering Department

801 Leroy Place

Socorro, NM 87801Ph: 505-835-5839 Fx: 505-835-5332 teare@ee.nmt.edu

Composite Mirror Applications 1638 S. Research Loop, Suite 100 Tucson, AZ 85740

Ph: 520-733-9302Fx: 520-733-9306

robertromeo@compositemirrors.com robertmartin@compositemirrors.com

Classification: FOUO

1.0 Use of Carbon Fiber Reinforced Polymer for Optical Telescopes

Carbon Fiber Reinforced Polymer (CFRP) has been used successfully in the past for manufacture of high strength components and has recently been used in production of optics [1-3]. It offers a low coefficient of thermal expansion (CTE), has a higher thermal conductivity than glass and can have many of its parameters tuned during manufacture [2,4-5]. It is very lightweight offering more than an order of magnitude reduction in weight over a comparable steel and glass optical system. As all components are made from the same material, CTE mismatches do not occur.

The use of CFRP as an optical surface requires a polished glass mandrel to use as the replicating medium, which must have the inverse shape of that which is desired after the replication [1,4]. As these tests are on optical flats, the replication produces an exact copy of the mandrel surface. CFRP material is laid over the highly polished mandrel and cured in an autoclave. The CFRP mirror and support structure are then removed from the mandrel and the process can be repeated many times to produce replicated mirrors [3]. This offers a large reduction in cost when many optics are produced.

The Naval Research Laboratory and Composite Mirror Applications have teamed up in the past to demonstrate meter-class optical telescopes for use in the Naval Prototype Optical Interferometer (NPOI) [1-5]. This paper focuses on proving better optical quality production.

2.0 CFRP Optics and Systems

Past optics manufactured for this program have been made at better than 0.25 wave RMS (visible) optical quality up to 0.4 meters. However, the push of this work is to demonstrate better optical quality by using a new CFRP material that should result in mandrel-limited optical performance than can be scaled up to 1.4 meters in diameter for use at the NPOI.

Figure 1. Schematic of 0.4 meter prototype telescope manufactured entirely from CRFP material.

Shown in Figures 1 and 2 are optical telescope assemblies that have been manufactured under this program in support of the Naval Prototype Optical Interferometer.

Figure 2. 1.4 meter CFRP telescope manufactured with optical blank. Final polishing of the mandrel will be completed soon and then the1.4 meter primary mirrors can be replicated.

3.0 CFRP Optic Under Test

The CFRP optics tested here were replicated from a 12 inch pyrex flat mandrel, polished to 0.1 waves RMS surface, 0.25 waves peak to valley. Three CFRP optics were replicated, all 4 inches in diameter from the same segment of the mandrel. The surfaces were rigidized with a support backing structure resulting in a 0.5 inch thick mirror. The CFRP mirrors were 65 grams in weight, which is half of a comparable glass mirror. Larger weight savings are obtainable when

larger diameter optics are manufactured. Typical weight savings when manufacturing meter class optics is around a factor of 50 to 100, depending on operating environment, constraints and desire for actuation.

Figure 3. 4 inch rigid replicated CFRP optic under test in this paper.

4.0 Optical Measurements: 4-D Interferometer Results

A 4-D interferometer was used at the Naval Postgraduate School to measure one of the 4 inch CFRP optics. Shown in Figure 4 are the 4-D screenshots with 0.07 waves peak to valley and 0.013 waves RMS at 632nm on a 1 inch section of the mirror. Observation of any 1 inch section of the mirror yielded similar results. The bottom figure used a beam expander to fill most of the mirror and shows a 0.25 waves peak to valley error and 0.05 waves RMS error. The larger error is seen to be mostly astigmatism and is from the alignment of the beam expanding optics.

Figure 4. Two dimensional plot and interferogram from 4-D interferometer of 1 inch section of replicated CFRP optic. Observation of any 1 inch section yields similar results and all demonstrate an RMS surface error of around 0.1 waves in the visible.

Figure 5. 4-D Interferogram showing 0.25 waves peak to valley error mainly resulting from uncalibrated alignment of expansion optics.

4.1 Optical Measurements: Zygo Results

A 4 inch Zygo Interferometer was used to measure the surface of the replicated CFRP mirrors after curing but before coating. Coating stresses are an issue with flat mirrors that are generally corrected in the design of curved mirror surfaces. The Zygo Interferometer measured a 0.1 wave RMS from the glass mandrel and 0.1 wave RMS from all of the CRP replicas. This is consistent with the measurements from the 4-D Interferometer.

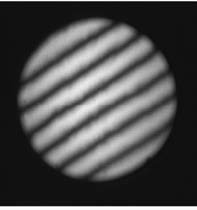

Figure 6. Interferograms taken from 4 inch Zygo Interferometer of mandrel (left) and replicated 4 inch CFRP optic. Both yield 0.1 waves RMS (visible) optical quality.

5.0 Temperature Change

The manufacture, coating and stability of optical flats is the most challenging problem when using CFRP materials, as small changes in stress can result in a measureable figure change. This problem is not as severe with curved optical surfaces. In large optics, such as the meter-class CFRP telescope, adaptive correction can be used for small figure changes.

Shown below are two Zygo Interferometer images taken with the fringes nulled before (left) and after (right) a 2 degree temperature change. This change added roughly 0.5 waves of defocus.

Figure 6. Zygo interferogram showing curvature change with small temperature change.

6.0 Conclusions and Future Work

CFRP optics were replicated from a polished Pyrex glass mandrel and both the mandrel and replicated mirrors were measured with both a 4-D Interferometer and a Zygo Interferometer to show that both the mandrel and all optics were 0.1 waves RMS (visible) wavefront error or less. This demonstrates that the CFRP material produces mandrel-limited optics. These results have only been achievable recently with the introduction of new CFRP materials in the market. Proof of mandrel-limited optical quality will spur future work in optimizing the 1.4 meter glass mandrel and replication using the new material so the telescopes can be configured and implemented at the NPOI. Additional future work will focus on comparing all three optics in addition to temporal stability.

REFERENCES

1. J. R. Andrews, S. R. Restaino, C. C. Wilcox, S. W. Teare, T. Martinez, J. Clark, J. Walton, R. Romeo, and R. Martin, “The 1.4 meter lightweight carbon fiber mount for the Naval Prototype Optical Interferometer,” Proc. SPIE 6306, (2006).

2. S. W. Teare, T. Martinez, J. R. Andrews, C. C. Wilcox, S. R. Restaino, R. Romeo, R. Martin, and D. Payne, “A lightweight adaptive telescope”, Proc. SPIE 6306 (2006).

3. J.R. Andrews, S.R. Restaino, T. Martinez, C.C. Wilcox, F. Santiago, S.W. Teare, R. Romeo, R. Martin, D. Wick, “Prototype 0.4 meter carbon fiber reinforced polymer (CFRP) telescope: specifications and initial testing,” Proc SPIE 7018 (2008).

4. C. C. Wilcox, J. R. Andrews, S. R. Restaino, T. Martinez, S. W. Teare, R. Romeo, D. M. Payne, “Structural Analysis of the 0.4 meter Lightweight CFRP OTA at the NRL,” Proc 2006 AMOS Technical Conference (2006).

5. S.R. Restaino, J. R. Andrews, T. Martinez, F. Santiago, C. Wilcox, R. Martin, R. Romeo, D. Wick, S. W. Teare, D. Payne, “Carbon Fiber Reinforced Polymer (CFRP) telescope program at NRL: an update,” Proc 2007 AMOS Technical Conference (2007).